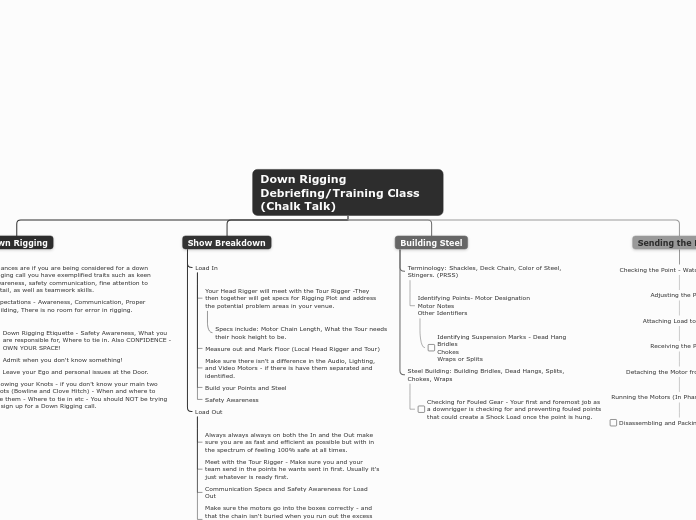

Down Rigging Debriefing/Training Class (Chalk Talk)

Down Rigging

Chances are if you are being considered for a down rigging call you have exemplified traits such as keen awareness, safety communication, fine attention to detail, as well as teamwork skills.

Expectations - Awareness, Communication, Proper Building, There is no room for error in rigging.

Down Rigging Etiquette - Safety Awareness, What you are responsible for, Where to tie in. Also CONFIDENCE - OWN YOUR SPACE!

Admit when you don't know something!

Leave your Ego and personal issues at the Door.

Knowing your Knots - if you don't know your main two knots (Bowline and Clove Hitch) - When and where to use them - Where to tie in etc - You should NOT be trying to sign up for a Down Rigging call.

Show Breakdown

Load In

Your Head Rigger will meet with the Tour Rigger -They then together will get specs for Rigging Plot and address the potential problem areas in your venue.

Specs include: Motor Chain Length, What the Tour needs their hook height to be.

Measure out and Mark Floor (Local Head Rigger and Tour)

Make sure there isn't a difference in the Audio, Lighting, and Video Motors - if there is have them separated and identified.

Build your Points and Steel

Safety Awareness

Load Out

Always always always on both the In and the Out make sure you are as fast and efficient as possible but with in the spectrum of feeling 100% safe at all times.

Meet with the Tour Rigger - Make sure you and your team send in the points he wants sent in first. Usually it's just whatever is ready first.

Communication Specs and Safety Awareness for Load Out

Make sure the motors go into the boxes correctly - and that the chain isn't buried when you run out the excess chain from the chain bag. Make sure the hook and bag are in appropriate spots inside the road case.

When running motors out - always watch to make sure the chains don't run themselves completely out of the body of the motor. Also watching for if the motor is running "out of phase" and watching to make sure the links don't bind up and get twisted in the motor body.

Building Steel

Terminology: Shackles, Deck Chain, Color of Steel, Stingers. (PRSS)

Identifying Points- Motor Designation

Motor Notes

Other Identifiers

Identifying Suspension Marks - Dead Hang

Bridles

Chokes

Wraps or Splits

Steel Building: Building Bridles, Dead Hangs, Splits, Chokes, Wraps

Checking for Fouled Gear - Your first and foremost job as a downrigger is checking for and preventing fouled points that could create a Shock Load once the point is hung.

Sending the Point

Checking the Point - Watching for Fouls

Adjusting the Point

Attaching Load to Motor

Receiving the Point

Detaching the Motor from the Load

Running the Motors (In Phase, Out of Phase)

Disassembling and Packing the Hardware -