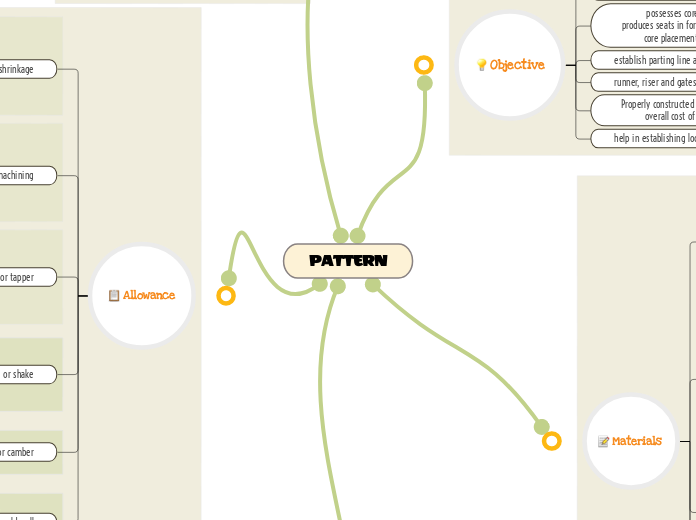

Objective

it form mould cavity for casting

possesses core prints which

produces seats in form of extra recess for

core placement in the mould.

establish parting line and parting surface

runner, riser and gates may be part of pattern

Properly constructed patterns minimize

overall cost of the casting.

help in establishing locating pins

Materials

Wood

most common, light weight, affordable

good surface finish

1.susceptible to shrinkage and warpage

2.short life span due to moisture

3.wear and tear

4. cannot withstand rough handling

shisham, kail, teak wood, mahogany

metal

for large number of casting

ADV: not affected by moisture

less wear and tear

longer life span

withstand corrosion

good strength to weight ratio

DISADV: high cost

high weight

tendency to rust

cast iron, brasses bronze , aluminium alloys

plastic

lighter, stronger resistance to moisture and corrosion, non sticky to mould sand and durale

fragile, breaks under sudden loading, may need metal reinforcement

thermosetting resin, phenolic resin

plaster

easily cast and worked with wooden tools

ADV: high compression strength

high expansion setting type which compensate

for the shrinkage allowance of the casting metal

wax

excellent for investment casting

paraffin wax, shellac wax, bees-wax, cerasin wax and micro-crystalline wax

Types

one piece (solid pattern)

two piece (split pattern)

cope and drag

three piece (multi piece)

loose piece

match piece

follow board

gatted

sweep

skeleton

Segmental (part pattern)

Allowance

shrinkage

liquid contraction: contraction during the period in which the liquid cool down due to pouring

solidifing contraction: contraction due to cooling to solid

contraction till it reaches room temperature

machining

+ve allowance given to compensate metal lost during machining

depends on size of casting, method of machining and finishing

3 to 8 mm

draft or tapper

+ve allowance given to all vertical surface

easier withdrawal

depends on size and moulding method

10-55mm/mt

rapping or shake

pattern rapped to increase size of cavity

-ve, only for large casting

0.5 to 1.0mm

distorsion or camber

applied to casting which have tendency to distort when cooling due to thermal stress

mould wall

mould wall movement

due to static pressure at the surface layer of sand at mould metal interface

Factors affecting

selection of

material

number of castig

type of mould material

process of moulding

method of moulding

degree of dimensional accuracy

minimum thickness

shape, complexity and size

cost