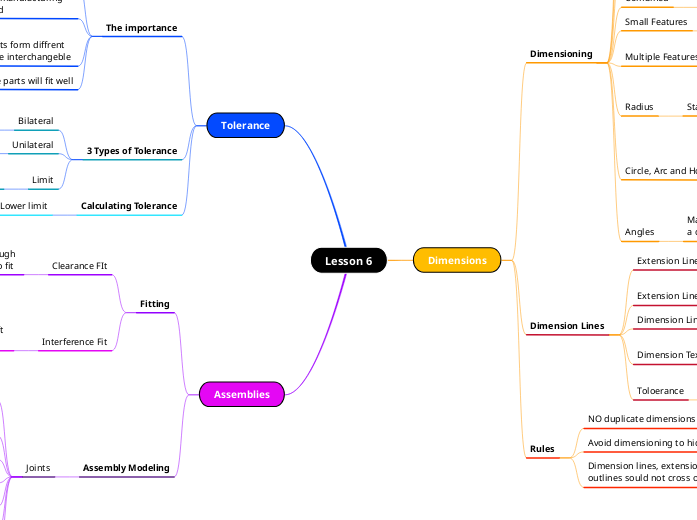

Lesson 6

Dimensions

Dimensioning

Parallel/Datum

consist of several dimension origination from a common reference aka datum

Superimposed Running

Simplifies dimensions to reduce the space used on a drawing

Chain

Indicates the dimensions individually

Should only be used if the function of the object will not be affected by accumulated tolerances

Combined

Uses both Chain and parallel dimensioning

Small Features

Arrowheads place outside the extension lines

Multiple Features

Use N x Dimension for multiple same dimensions

Radius

Starts with R

Line to indicate centre start form centre

Just dimension is center is not needed

Circle, Arc and Hole

Circle

Diameter

Arc

Radius

Hole

located by their centerlines

Angles

Marked with curved dimension line and has a degree symbol

Dimension Lines

Extension Line offset

The gap between object and extension line

Extension Line

Extended line form the surface of the object to establish the size of the dimensions

Dimension Line

Has an arrowhead on each end

Dimension Text

Base dimension (mm)

At the bottom corner of the drawing

Toloerance

Define how much deviation from the dimension is allowed

Rules

NO duplicate dimensions

Avoid dimensioning to hidden lines and features

Dimension lines, extension lines and object outlines sould not cross or overlap

Tolerance

The importance

Prevent high rejection rates

To identify the manufacturing method needed

To ensure parts form diffrent companies are interchangeble

ensure quality control for parts form different companies

Ensure the parts will fit well

3 Types of Tolerance

Bilateral

Vary in 2 directionn many not be the same amount of tolerance

Unilateral

Vary in only 1 direction

Limit

The upper and lower limits of the dimension

Calculating Tolerance

Upper limit - Lower limit

Assemblies

Fitting

Clearance FIt

There will always be enough clearance for the shaft to fit

e.g. door hinge

Shaft is smaller than the hole

Allows 2 parts to move

Interference Fit

There will always not be enough clearance for the shaft to fit

Shat is bigger than the hole

Difficult to move or remove

Assembly Modeling

Joints

Rigid

Joins 2 components together no movements

Revolute

Single rotational degree of freedom like a hinge

Slider

Cylindrical

Pin Slot

Planar

Ball