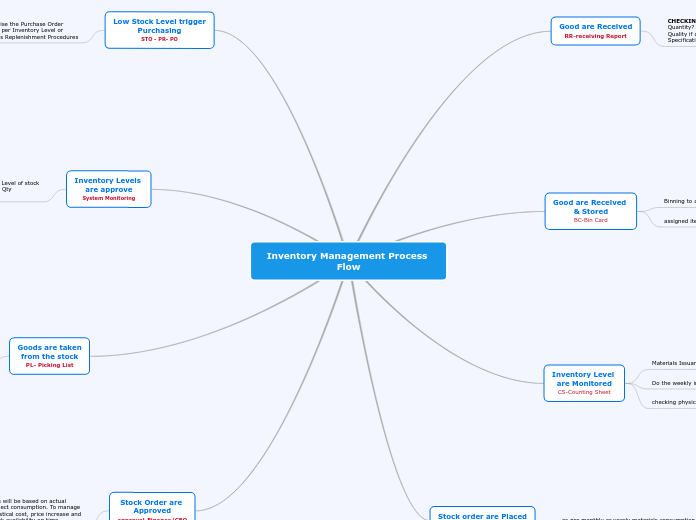

CHECKING

Quantity?

Quality if damage?

Specification?

Binning to a location

assigned item to proper location

Materials Issuance has been done

Do the weekly inventory

checking physical vs. system qty

as per monthly or yearly materials consumption

Raise the Purchase Order

as per Inventory Level or

Materials Replenishment Procedures

Setting Re- Order Level of stock

* Minimum order Qty

* Re- order Qty

Controller must check the allocation

of every stock on hand before

issuing to any particular JO

This will be based on actual

Project consumption. To manage

logistical cost, price increase and

stock availability on time.