My Crystal Ball

Now

BIM

Its here, its now, so who here is using it?

It's also the foundation for our future...

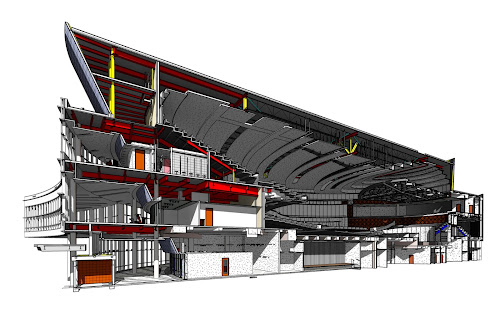

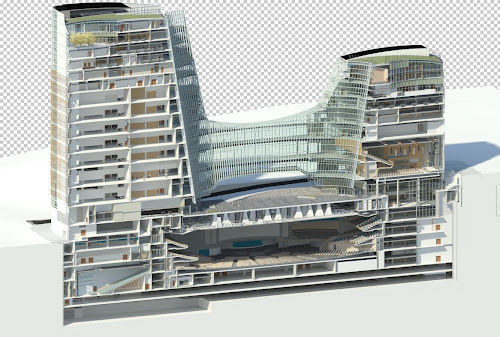

Design vs. Construction Models

BIM based Estimating

Quantites are a natural byproduct of BIM

Using these is no different than using drawings, napkin skethces, etc...

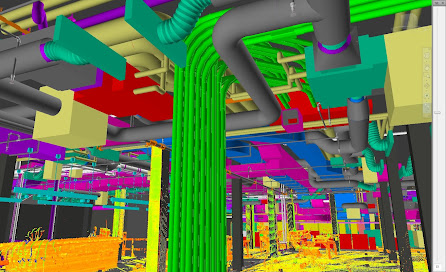

CNC Fabrication

This is how a vast majority of the things we use get made.

AEC is behind the curve, but catching up.

Subs have been doing this for years, and we only now have a process to support them.

Nothing is stopping us from taking control and leading this process to get better results.

Prefabrication

Prefabrication is already the norm for many project types or scopes.

It has some serious benefits to cost, schedule, quality, etc...

The only real downside is that it requires more planning.

3D Printing

A great Design tool

A great sales tool

Really, just a toy for AEC

3D Coordination

Nothing more than coordinating using current technology.

Not sophisticated anymore.

Prefab is the key to capturing value.

Expanding scopes.

Scheduling

4D Scheduling is just associating the tasks and their time spans with 3D opjects.

Communication

Schedule Analysis and Optimization

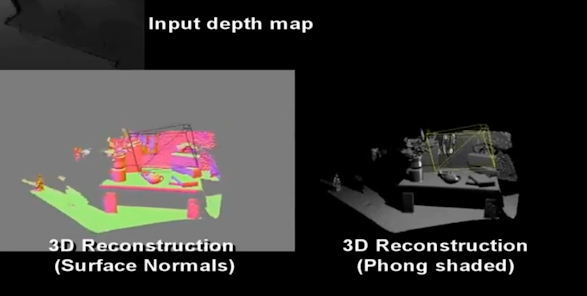

Laser Scanning

Bridging the gap between our virtual buildings, and the real ones.

Already cheaper than most alternatives in the long run

If you aren't using them, it's time to start.

Barcodes and QR Codes

Not just for your grocery store anymore.

For any manufactured/installed item, it is a way to link BIM with Reality

Somewhat limited built in data, dependent on links

Not a lot of "Killer Apps" yet.

Discrete Energy Analysis

Being pushed into the hands of designers

Not just for engineers anymore

Graphics-centric tools for communication

Accuracy is highly questionable

Field Use of BIMs

The last place BIM doesn't tread heavily.

The concepts are there today, but the hardware and software isn't

Changes over the next two years will make BIM accessible to anyone, anywhere, at any time, on any device.

Tools and workflows will follow

Soon

BIM 2.0

The rise of social-awareness in BIM objects

Full parametric relationship support across objects and files

Some ability to link objects across format types

This is what is required for collaboration to really work

Realtime Rendering

The technology is here, for other industries (low poly counts).

Opens up a whole new world for designers.

Communication with clients, etc...

Very expensive software, very expensive hardware

Detailed Analysis

Really, this is just a refinement of the generalized analysis tools we have now.

Current tools are built on last generations data sources

Building Analysis based on detailed BIMs

Enabled by continued improvements in computation / data.

Enabled by growing sub-metering

Sub-metering is no longer enough detail

Think thousands of sensors in a single building

Micro-metering provides individual level feedback on building performance

Or object level information on system performance

The Cloud(s) are gathering

Cloud computing becomes monetized (not just Beta anymore).

Software as a service for emerging technologies, learn to subscribe.

Unlimited Computing* brings some computations down to earth, at a cost.

Collaboration is changing, as is ownership of information.

Photogrammetry/Videogrammetry

Supplementing or replacing laser scanning

Allows ubiquitous and real time data capture

Can truly bring the virtual and physical worlds into parity

Just another type of sensor

RFID / NFC

Why scan something when you can just know?

On demand reporting

Live tracking with jobsite sensors

Can call up a wealth of information

3D Fabrication

Tools already exist in manufacturing to 3D print finished goods.

This will expand to AEC allowing custom fabrications with complexity / detail not previously affordable.

Will this usher in a new era of ornamentation?

Not Soon Enough

Mass Customization is easier for our industry than for manufacturing

We already make one-off custom products

For us, this is a way to lower the cost and time required to deliver what we already deliver

Some trades will have their work replaced by machines out on the jobsite

Union pressures, decreasing talented labor pools, increasing cost of labor, etc...

Decreasing cost of robotics and other mechanized production tools

Software is rapidly developing to help machines "learn" techniques and processes

Building Fabrication Process Consolidation

Wherever possible, processes that can be melded will be

If you can fabricate in 3D, and Install robotically, why not fabricate on site in the final installtion location?

More will be done virtually up front, and actual construction will occur more rapidly on the back end after all the details are worked out

Environment Simulation

Discrete Analysis will give way to wholistic environment simulations.

Provides multiple levels of simulation feedback

Visualization of compounding decisions

Design in Analysis environments

Single Model Database

Many modeling tools will access a single database

This will support multiple definitions of objects

Multiple LODs

Fully parametric linkages

Reduce cross platform compatability issues

Enable many additional workflows

No More Drawings

Drawings will be orphaned as a means for Fabrication

Not needed for installation

Already orphaned for coordination and design.

And will be orphaned for code review / permiting

So, why waste time making them anyway?

Hardware and software advances

Supports a fundamental merger between the virtual and phyisical "existence" of objects.

Massive data flows requiring advanced compression and storage tools.

Local Positioning Systems

The problem is accuracy

Required for automated robotic installation or in-situ fabrication

Supports VR or VA interfaces

Networked Objects

Chairs, VAVs, and even toilet paper rolls will eventually become networked.

IPv6

Mimic the progress of BIM from self-awareness to social-awareness.

Visual Augmentation

Fancy way of saying your glasses or contacts have displays integrated.

Superimposition of useful information in your FOV.

Let's you see what isn't there yet.

Soapbox

BIM

State = Completeness

Scale = LOD

Model = Analysis

</ "BIM Model">

Integration

Enterprise vs. Collaboration

Vertical vs. Horizontal

Sustainability

Ranking Systems don't really matter

All about lifecycle

Trends

Risk/Reward

Risk will continue to migrate downstream to contractors and subcontractors.

With risk goes reward, so to make money, you have to take on risk, not place it on others.

With less money for design, drawings will continue to have less information, and less coordination.

Ownership of Design

Cloud Computing

Contractual changes

Design as a "service"

Buildings as a "product"

IP/Patent reform

Incentives for Innovation

New contract structures MUST encourge innovation

Change will not occur unless it is rewarded

This is where DB / IPD can really add value

Renovations / New Construction

Increasing focus on rehabbing current building stock

What to do with no BIMs?

Driven by economy, and sustainability.

Increasing LOD

Will continue to place demands on available hardware and software.

Model more, earlier...

Who has the time (or fee) to do this modeling?

How do you manage so much information?

Unlimited / Cloud Computing

What is the cloud REALLY about?

Unlimited processing power

Collaboration

Will be a subscription cost (SAS)

Who owns the data?

Continual Education

Technical skills have a short life span

I am proficcient in about 15 different professional software tools

In ten years, I'll need to know about 50

And the 15 I know will be gone