jonka Alexandre de Pommery 6 vuotta sitten

1363

Supply Chain Mgt at Apple_Alexandre de Pommery

jonka Alexandre de Pommery 6 vuotta sitten

1363

IE Business School

Alexandre Berthe de Pommery

MiM Section 3

Prof. Felipe Quintana

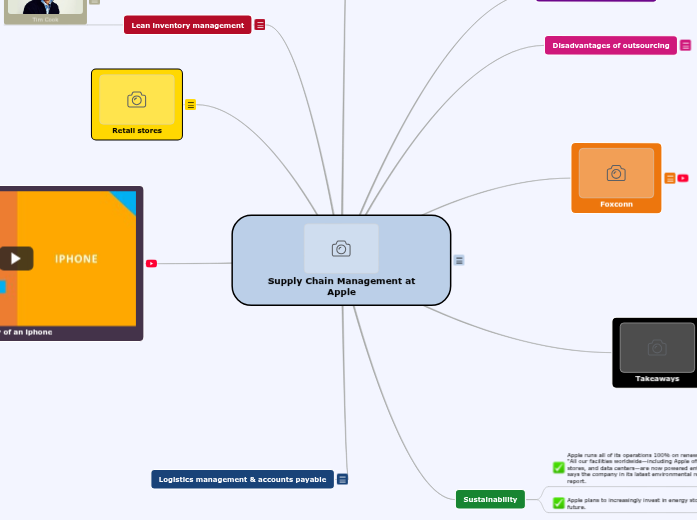

I chose Apple because it is the perfect example of a globalised value chain. While the product designs are made in California, Apple's products are manufactured and shipped all over the world. Today, Apple is considered to be the global leader in supply chain management. This mind-map will explain you why.

90 day terms with suppliers for accounts payable: Apple accounts payable represent 18% of its sales, compared to 8% for its competitors.

Apple stores are famous worldwide for their design and customer experience. Fun fact: more pictures are taken of the Apple store in Manhattan than of the Statue of Liberty!

Apple has the highest sales per square foot in retail (almost five thousand dollars).

Customer service at Apple stores is very efficient, with advisers always available for clients to offer personalised help. Apple also repairs its product in-store to collect more information about the defaults and thus improve the quality of its offer.

Thanks to Apple's contract manufacturing model, products are shipped directly from contract-manufacturers to the client's doorstep in a matter of days, without Apple being much physically involved in the process. Apple still gets to book all the revenue but the product goes from a contract manufacturer, to a third-party shipping company, to the customer (cost of inventories are shifted to the suppliers). Inventory turnover times are so high that it makes the whole operational structure incredibly efficient and direct. Apple has thus the best inventory turnover in the business, because inventories stay on its balance sheet for a very short time.

Moreover, by using inventory tracking mechanisms, Apple squeezes its suppliers by making sure that the quotes their suppliers generate are grounded in the truth, allowing the company to have a better control over its operations.

Although they still do have inventories for they stores, they keep their inventories very lean (CEO Tim Cook hates inventories) through this direct delivery process right after production.

Apple's CEO Tim Cook is mainly responsible for this lean management and contract manufacturing model. Before he took over as CEO, he had ten year experience in operations for the company. He scrapped all Apple's in-house warehouses and manufacturing facilities and went to contract manufacturers. This changed the ability from Apple to manage with the huge demand and make profits.

Tim Cook uses the dairy industry to talk about inventories, "like the milk in fridge, the longer it sits the more likely it is to go bad". The aim at Apple is to turn inventories very quickly. Apple has inventories turnover comparable to those of supermarkets and fast food chains.

Apple's successful supply chain management relies on its international contract-manufacturing model, enabling it to keep inventories lean and low (which means low inventories cost) and a very high inventory turnover. It also allows the company to be responsive to changes in demand.

It is a very good example of how outsourcing can benefit a global company. However, Apple must be careful to keep as much control as possible over the quality and working conditions of its suppliers, and must continue investing in renewable energies to build a sustainable value chain.

Foxconn is one of the world's largest manufacturing plant and was targeted by many journalists because of its controversial working conditions. It is one of Apple's biggest manufacturer. According to an article from the New York Times, "the facility can produce 500,000 iPhones a day, or roughly 350 a minute".

Although Foxconn is essential for Apple, it represents a risk for its brand image because of the bad ethical reputation.

Please click on the Youtube icon to watch the video (I was not able to directly insert it for property rights reason).

Issues with Apple's contract-manufacturing model:

Advantages of outsourcing and contract manufacturers model for Apple: